Revolutionize Your Operations with Cutting Edge Solutions

Ethanol & Corn Wet Milling Operations Products

Streamline Production & Enhance Your Productivity

In today’s fast-paced industrial landscape, downtime is not an option.

At Water Tech, Inc., we understand the critical importance of efficiency, safety, and reliability in ethanol and corn wet milling operations. We provide a suite of advanced products tailored specifically to streamline your processes and enhance your productivity. Our innovative solutions not only ensure cleaner equipment but also contribute to a safer working environment while optimizing production time.

Cutting-Edge Solutions to Tailored to Your Needs

Water Tech, Inc. offers a comprehensive range of products tailored to meet the unique demands of ethanol and corn wet milling operations. By investing in our innovative solutions, you’re not just enhancing your production; you’re securing your future in the industry.

Chemical Solutions for Co-Product Recovery

At Water Tech, Inc., our products aim to enhance corn oil and protein recovery, revolutionizing the conventional distillation process. By using our aqueous solutions and organic acids, you enhance energy conversion and reduce energy consumption significantly.

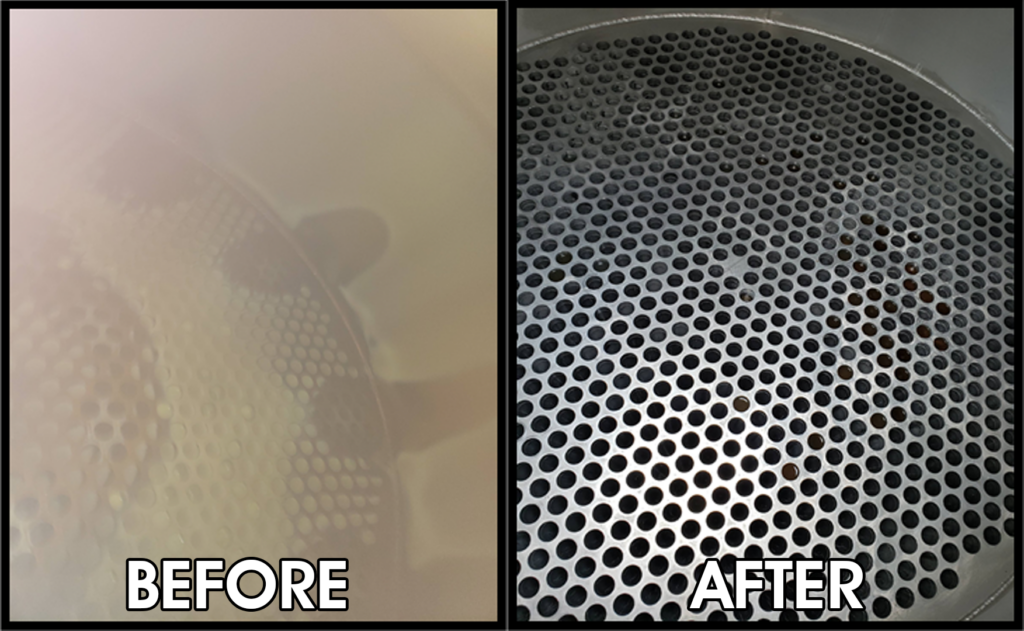

ScaleBreak – Clean In Place Solution (CIP)

Cleaner, safer, and faster CIP aid, reducing equipment downtime and hydro-blasting frequency.

– Cleaner: ScaleBreak© can be utilized for CIP of essentially any equipment traditionally cleaned with caustics, making it an ideal replacement for caustics.

– Safer: ScaleBreak is safer than caustics for your team, your equipment, and the environment, with no extreme hazards.

– Faster: ScaleBreak outperforms traditional caustic cleaning programs by reducing cleaning time and potentially eliminating the need for hydro-blasting.

– Increase Production Time: ScaleBreak’s low-foaming formula results in faster cleaning cycles that increase production time.

Anti-Foam Chemistry

Plant-specific anti-foam formulations for specific applications within ethanol and corn wet milling plants. Our chemical solutions keep surface foam, existing foam, and bubble walls under control in your industrial processes.

Deposit Control Chemistry

Building on our industry-leading ScaleBreak© technology, Water Tech has developed the first truly effective Deposit Control Agents for Ethanol Producers and Corn Wet Milling Operations. Working synergistically with ScaleBreak, our ScaleTrol products maintain clean heat transfer surfaces, and reduce the need for expensive mechanical cleaning.

Equipment for Co-Product Recovery

Our specialized equipment ensures precise and efficient application, even in hard-to-reach places. With Water Tech, Inc., your production costs decrease while your actual profits soar.

Portable CIP Skids

Portable CIP skids play a crucial role in ethanol production by facilitating efficient and automated cleaning processes.

– Time and Labor Savings: Mobile CIP systems save time and labor by eliminating the need for manual cleaning processes, improving overall efficiency.

– Consistent Cleaning: Portable CIP skids provide consistent and repeatable cleaning procedures, ensuring that equipment is thoroughly cleaned every time.

– Reduced Contamination Risks: Proper cleaning with CIP systems reduces the risk of cross-contamination, ensuring the quality and safety of ethanol products and co-products.

– Extended Equipment Life: Regular cleaning with ScaleBreak and ProBreak, facilitated by CIP skids, helps extend the life of industrial equipment by preventing the buildup of scales and other deposits.

Take Your Operations to the Next Level.

Contact Water Tech, Inc. today to discover how our cutting-edge solutions and equipment can help you streamline production, reduce downtime, improve safety, and optimize efficiency. Reach out to us now and experience the Water Tech difference!